Industry Background

With the explosive growth of renewable energy, energy storage has become an indispensable support for the new power system. In particular, electrochemical energy storage has become one of the key technologies to ensure the consumption of renewable energy, enhance the flexibility of the power system, and support the safe and stable operation of the new power system.

However, due to the risk of thermal runaway in lithium battery energy storage, fire incidents in energy storage systems have occurred frequently. According to incomplete statistics from the Zhongguancun Energy Storage Industry Technology Alliance, from 2011 to September 2024, a total of 89 energy storage safety incidents have occurred worldwide. Safety has thus become one of the major bottlenecks restricting the development of the energy storage industry.

In response to this challenge, the industry urgently needs to adopt effective measures to ensure the safety and reliability of energy storage systems. Advanced firefighting technologies and innovative safety management strategies are crucial to ensuring the stable operation of energy storage systems.

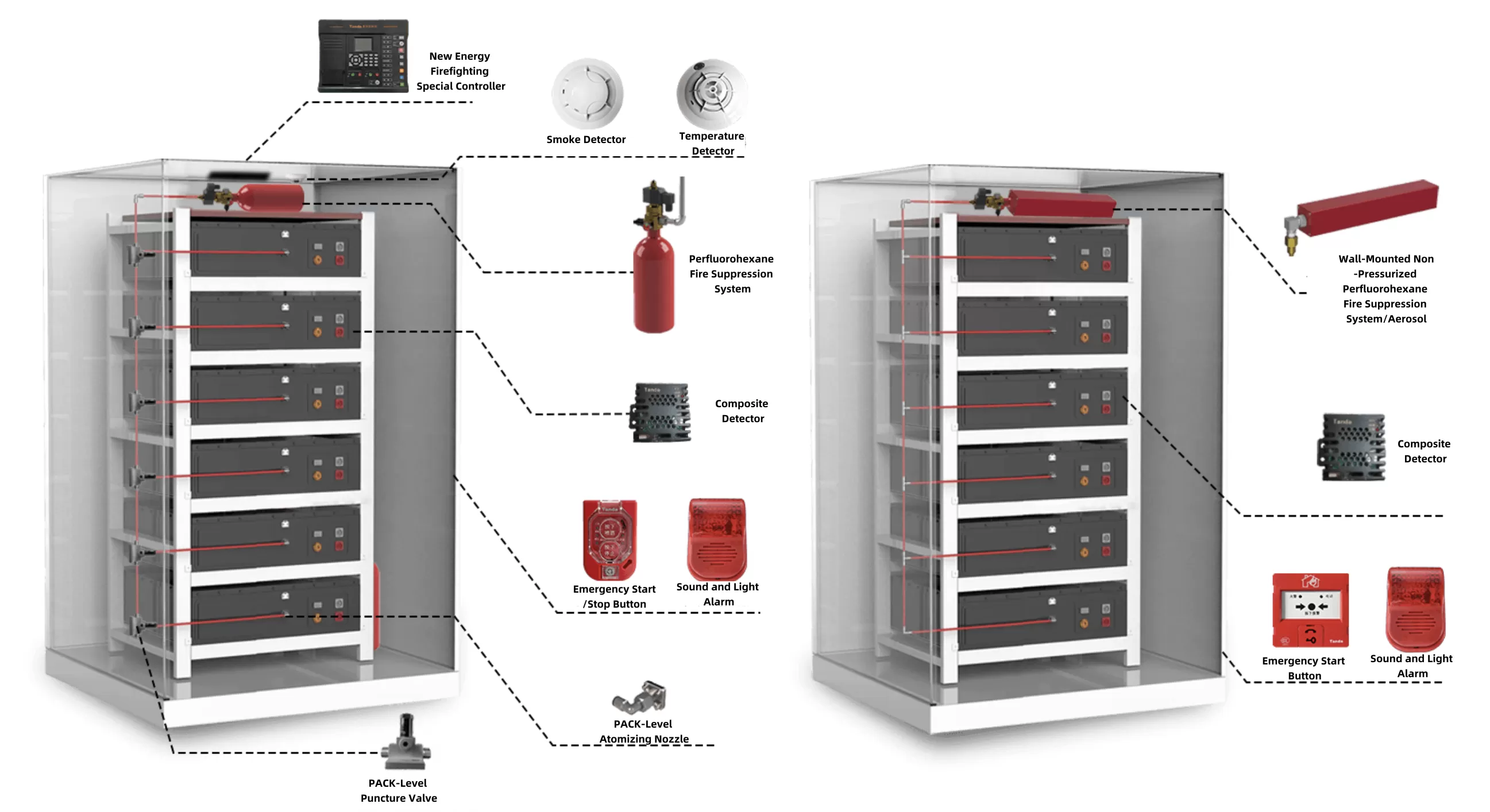

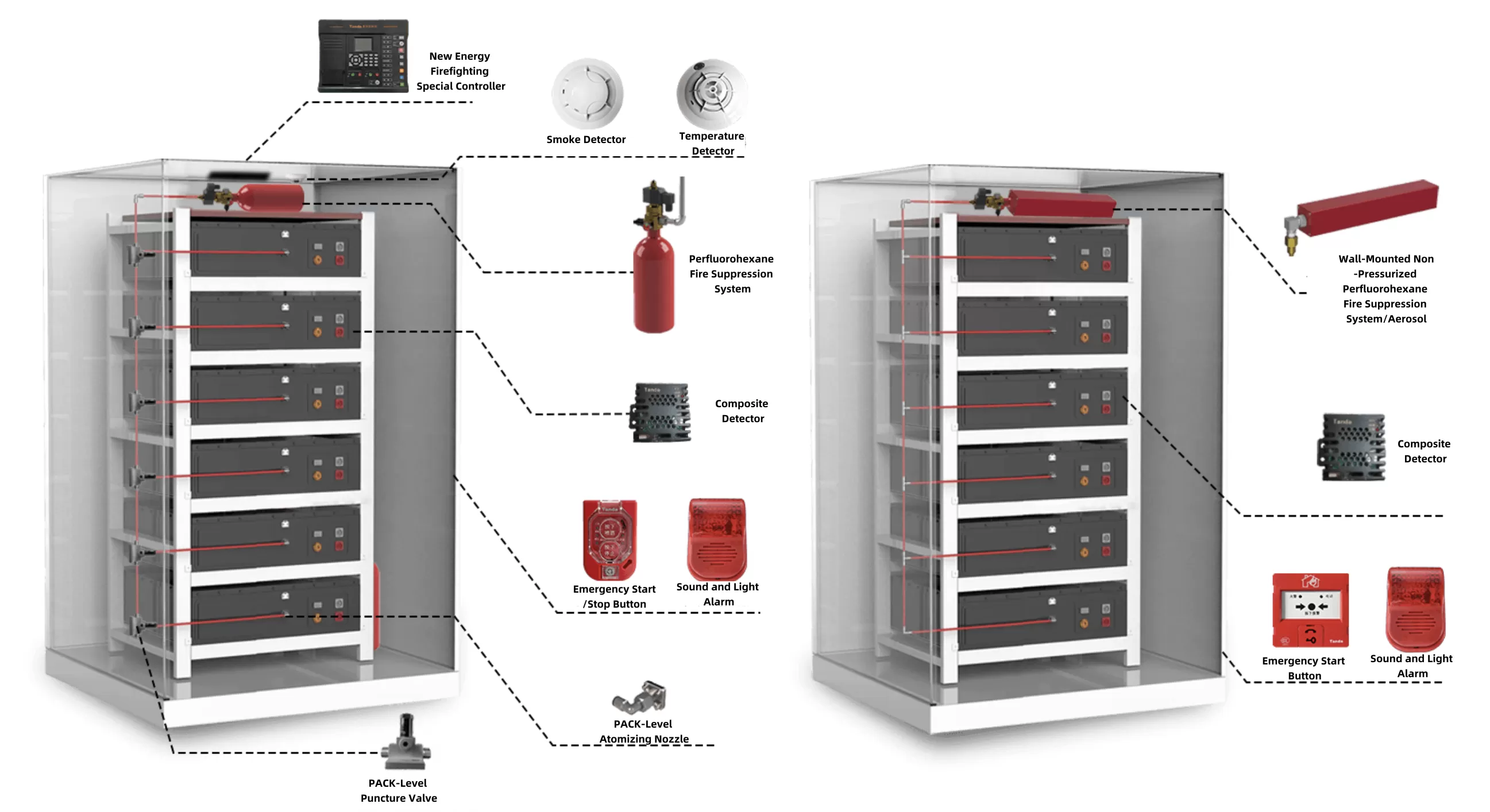

Prefabricated Energy Storage Firefighting Solution

Key Advantages:

Four-Level Protection: Four layers of firefighting protection at the Pack level, battery cluster, battery room, and station level, achieving "early warning and fine control."

Full Station Interconnection Control: Monitoring and early warning systems are linked with the station-level firefighting host, enabling real-time monitoring of data within each cabin.

National Standard Certification: Controllers, detectors, and audible and visual alarms are all CCC certified, and the host system holds dual certifications for "fire alarm + gas fire suppression."

Commercial and Industrial Energy Storage Firefighting Solution

Key Advantages:

Reliable Detection: Smoke detection utilizes "red light + blue light" dual light source sensors, combined with a labyrinth structure to block false alarms caused by interference.

Extremely Early Warning: Automated production calibration workshops use high-precision imported sensors to achieve early detection, early warning, and early suppression.

Efficient Fire Suppression: With an integrated detection and control system, the solution can execute different logic for full spraying, cluster spraying, and cabin spraying. It enables "point-to-point" multiple delayed spraying cycles to ensure effective extinguishing of flames, temperature reduction, and suppression of re-ignition.

Wind Turbine Firefighting Solution

Key Advantages:

Stable and Reliable: Specialized alarm control equipment designed for wind turbines, resistant to strong magnetic interference and suitable for wind turbine environments, preventing false alarms, disconnections, and failures.

Full Stack Solution: Automatic alarm and firefighting systems are set up for individual wind turbine units. In the event of a fire, signals are transmitted to the central control room, promptly notifying personnel for action.

Cloud Monitoring: Firefighting signals are transmitted to the "Smart Firefighting Cloud Platform," enabling real-time monitoring of stations nationwide.

Lithium Battery Production Firefighting Solution

Key Advantages:

Production Safety: Provides a complete set of firefighting products for assembly line workshops, ensuring safe production processes.

Comprehensive Risk Monitoring: Ensures safety across the production process, with early detection and handling of abnormal situations.

Customization Advantages: Custom professional early-warning devices are available for production lines in the later stages of lithium battery manufacturing (such as formation and capacity testing), where fire risks are higher.

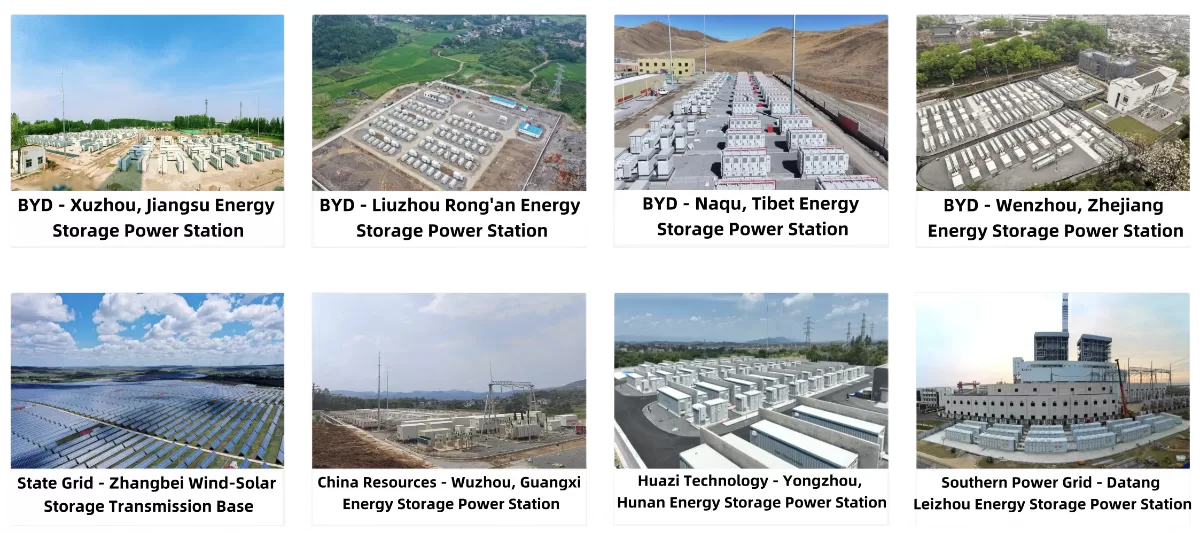

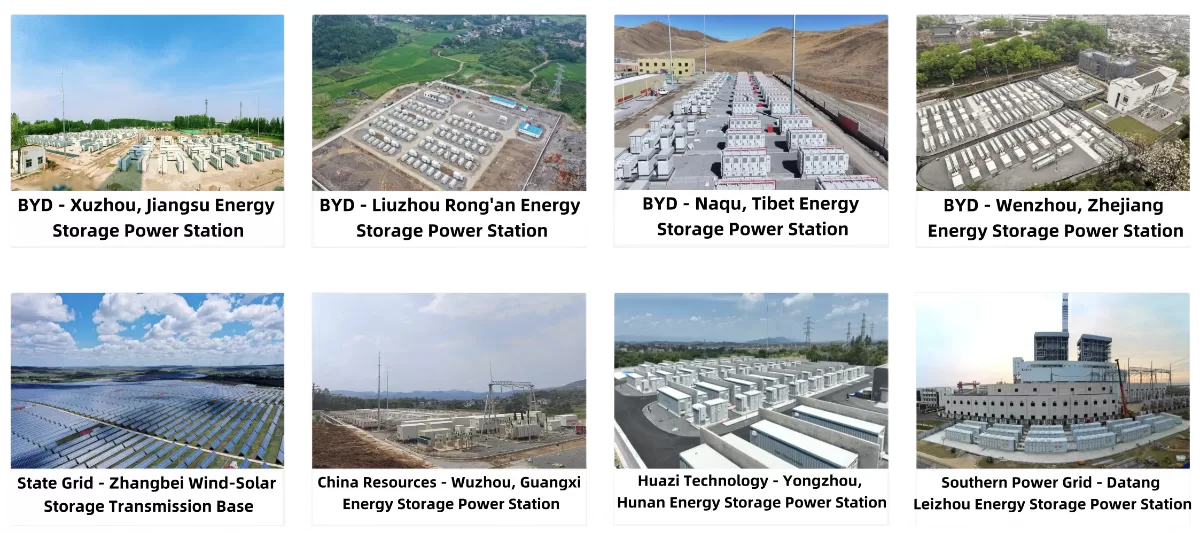

Application Project Cases